Your Gateway to Digital Manufacturing.

Leading India's Advanced Manufacturing Evolution.

Your Innovation Partner for Industrial-Grade SLA 3D Printing and Rapid Prototyping Solutions

Your Innovation Partner for Industrial-Grade SLA 3D Printing and Rapid Prototyping Solutions

- Advanced Manufacturing Solutions

- Quality Assurance Systems

- State-of-the-Art Technology

15+ Year Of Experience

- About Us

Accelerating Innovation with Advanced Additive Manufacturing Technologies

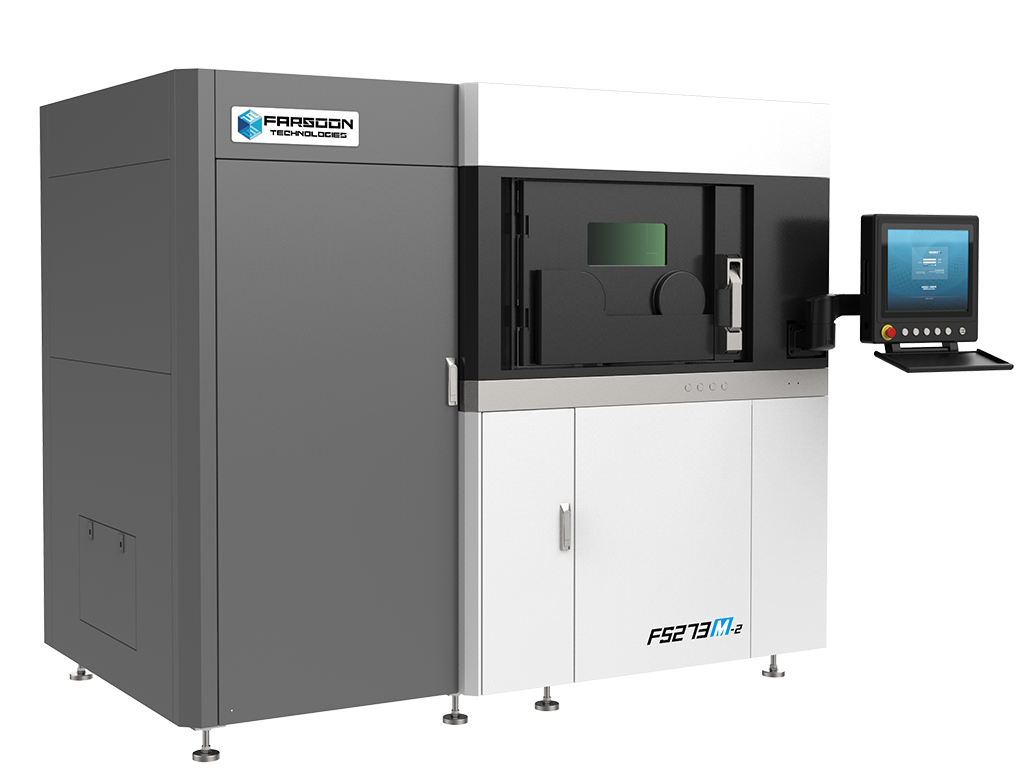

Founded in 2021, Schraffur Studios combines deep domain expertise with strategic global partnerships with technology leaders – Magforms (SLA) and Farsoon Technologies ( SLS & Metal – LPBF ). to deliver high-performance 3D printing solutions in India. Backed by an experienced team averaging over 12 years each in the field.

Our portfolio includes industrial-grade systems for polymers, metals, composites, and high-temperature materials—engineered to help manufacturers reduce lead times, streamline R&D, and scale production.

Partner with us to unlock next-generation additive manufacturing

- Our Partners

Exclusive Distribution Partnerships

Cutting-Edge Portfolio

From SLA to advanced materials and application-specific additive solutions — our offerings cover diverse needs across industries.

Culture of Innovation

R&D is at the heart of Schraffur. Our teams are encouraged to explore new materials, processes, and workflows, fueling continuous product evolution.

Community-Centric

We nurture a transparent, growth-focused workplace, celebrating individual passions and achievements through profit-sharing, bonuses, and career development programs.

Flexible Collaboration

With remote working options and flexible schedules, we trust our teams to deliver quality outcomes — anytime, anywhere.

A True Partnership

Schraffur’s service extends beyond machine installations. We offer training, application development support, AMC programs, and a 98.5% uptime guarantee to ensure uninterrupted innovation for our clients.

- Our Technology

Industrial 3D Printing Solutions

High-Performance 3D Printing for Precision, Versatility, and Rapid Production

At Schraffur Studios, we offer advanced industrial-grade solutions tailored to meet the diverse needs of modern industries. Whether you’re prototyping with high-performance plastic materials or manufacturing durable metal components, our technology delivers unmatched precision, speed, and flexibility.

Our high-end additive manufacturing capabilities help businesses accelerate product development, reduce production costs, and streamline manufacturing workflows. Perfect for rapid prototyping, functional parts, and production-scale applications, our solutions ensure exceptional dimensional accuracy, consistent output, and a superior surface finish.

Key Features of SLA & Metal 3D Printing Technology:

Large-Format & High-Speed Options

Our advanced systems support large-format production with rapid turnaround times, enabling the creation of complex, high-quality parts at scale—without compromising precision or surface finish.

High-Performance Additive Manufacturing Solutions

We specialize in versatile production technologies that support a wide range of applications—from early-stage prototyping to end-use parts—offering material flexibility and industrial-grade quality across multiple sectors.

Fully Automated Material Management

Our automated material handling system ensures seamless operation with minimal interruptions—reducing downtime and boosting overall productivity in production workflows.

Seamless Workflow Integration

Our advanced software tools simplify the entire production process—from preparation to execution—enhancing operational efficiency and ensuring consistent, high-quality results.

Exceptional Visual Quality & Precision

Deliver visually refined results with sharp, accurate features—ideal for professional applications that demand high standards of quality and definition.

Open Platform for Material Flexibility

Our open platform supports a wide range of advanced materials, giving you the freedom to tailor your production process to specific performance and application requirements.

- Why Choose us?

The Schraffur Team - A Collective Vision for Innovation

At Schraffur, our strength lies in the diversity and expertise of our multidisciplinary team. From engineers and designers to researchers and manufacturers, our team brings together a vast range of skills and perspectives

Additive Manufacturing Experts

With deep expertise in 3D printing technologies, we specialize in everything from basic prototyping to production-grade manufacturing with a focus on quality, precision, and speed.

Engineering & R&D

Our engineers and researchers work together to create cutting-edge materials and processes, constantly pushing the boundaries of what’s possible in additive manufacturing.

Business Strategy & Growth

We blend creativity with entrepreneurship, ensuring that our products and solutions meet real-world needs while driving business growth for both ourselves and our clients.

Engineering & R&D

Our engineers and researchers work together to create cutting-edge materials and processes, constantly pushing the boundaries of what’s possible in additive manufacturing.

Business Strategy & Growth

We blend creativity with entrepreneurship, ensuring that our products and solutions meet real-world needs while driving business growth for both ourselves and our clients.

- Industries We Serve

Tailored 3D Printing Solutions Across Diverse Sectors

Automotive & Product Design

Dental & Healthcare

Aerospace & Defense

Jewelry & Casting

Architecture & Urban Planning

Educational & Research Labs

- Industries We Serve

Tailored 3D Printing Solutions Across Diverse Sectors

Automotive & Product Design

From ergonomic mockups to functional prototypes, we assist in visual validation, assembly testing, and design iterations, helping automotive manufacturers reduce time-to-market and accelerate product development.

Key Benefits:

- Rapid prototyping for automotive components

- Improved design validation with high-quality models

- Fast iteration for testing parts and assemblies

Dental & Healthcare

Our biocompatible resins are ideal for producing crowns, bridges, and implant molds, advancing in-house digital dentistry processes. Schraffur’s 3D printing solutions enable precision and customization for healthcare professionals and dental labs.

Key Benefits:

- High-precision dental molds and prosthetics

- Customization for patient-specific needs

- Faster turnaround times in dental and healthcare applications

Aerospace & Defense

Our biocompatible resins are ideal for producing crowns, bridges, and implant molds, advancing in-house digital dentistry processes. Schraffur’s 3D printing solutions enable precision and customization for healthcare professionals and dental labs.

Key Benefits:

- High-precision dental molds and prosthetics

- Customization for patient-specific needs

- Faster turnaround times in dental and healthcare applications

Jewelry & Casting

With our castable resin workflows, jewelers can achieve intricate designs and fine detailing while expediting waxless production. Whether you’re designing prototypes or manufacturing final pieces, our technology ensures consistent quality.

Key Benefits:

- Fine detailing for jewelry design and casting

- Speed up the casting process with waxless production

- High-precision models for rapid design-to-production cycles

Architecture & Urban Planning

Create scale models, topographic representations, and zoning models with precision. Our 3D printing solutions allow architects to showcase designs with accurate facades, urban layouts, and presentation-ready models for stakeholders and clients.

Key Benefits:

- Detailed architectural and urban scale models

- Improved presentations with realistic visualizations

- Enhanced communication of design ideas and concepts

Educational & Research Labs

For universities and research labs, Schraffur provides a platform for rapid prototyping, innovation labs, and design thinking workshops. We help researchers and students bring their ideas to life with accessible, cost-effective 3D printing technologies.

Key Benefits:

- Support for academic and research-based prototyping

- Fostering innovation and creativity in education

- Efficient model development for experimental research

- Our technology Offering

Precision Technology, Powered by Innovation

SLA

SLA is a resin-based 3D printing technology that uses a UV laser to cure liquid photopolymer layer by layer. It delivers extremely high resolution, smooth surface finishes, and fine details—ideal for prototypes, dental models, and jewelry masters. Best suited for visual models and intricate designs.

SLS

SLS uses a high-powered laser to fuse powdered thermoplastic materials like nylon. It produces durable, functional parts without the need for support structures. Commonly used for rapid prototyping, small-batch production, and engineering-grade components.

Aerospace & Defense

LPBF is an industrial metal 3D printing process where a laser selectively fuses layers of metal powder. It enables the production of high-strength, complex metal parts with excellent mechanical properties—ideal for aerospace, automotive, tooling, and medical applications.

SLA is a resin-based 3D printing technology that uses a UV laser to cure liquid photopolymer layer by layer. It delivers extremely high resolution, smooth surface finishes, and fine details—ideal for prototypes, dental models, and jewelry masters. Best suited for visual models and intricate designs.

SLS uses a high-powered laser to fuse powdered thermoplastic materials like nylon. It produces durable, functional parts without the need for support structures. Commonly used for rapid prototyping, small-batch production, and engineering-grade components.

LPBF is an industrial metal 3D printing process where a laser selectively fuses layers of metal powder. It enables the production of high-strength, complex metal parts with excellent mechanical properties—ideal for aerospace, automotive, tooling, and medical applications.